|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Our production unit includes 50 skilled technictions who follow rigorous quality measures to bring out the best product in the markets. In house processing is done for the production of all the products. We carry out export orders according to the specified needs of the client and guarantee on time delivery.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| UNLIMITED DESIGN OPPORTUNITY :-

After more than a half century of steady, substantial growth in acceptance and popularity, modular hollow concrete block is an established building material . It is used in more than 2/3 of the total volume of all masonry walls. Yet many architects, engineers and builders are not fully aware of all its benefits and advantages . The structural attributes of concrete block are well - known. Strength, Durability. Fire-resistance. Thermal insulation. Sound absorption. Its modular dimensioning makes it easy for design and construction. Its economy and ease of installation are a welcome answer to rising costs. More and more imaginative designers are now taking advantage of the wide and increasing variety of shapes, sizes, laying patterns and surface contours (both conventional and decorative ) which provide almost unlimited design opportunities. Bharat Spun Pipe & Construction Co. is a leader of the concrete block industry, offers over 46 years of experience to offers a wide range of concrete masonry units & other Precast concrete products. We Bharat Spun Pipe & Construction Company is manufacturing the concrete hollow , solid, interlocking paving blocks by Columbia USA fully automatic concrete block plant with automatic batching and mixing plant & curing system. Modern concrete masonry units offer a broad spectrum of sizes, shapes, surface contours and laying patterns. Creative opportunities abound for enhancing buildings of all types and sizes: single - story or high rise, from residences, colleges and schools to commercial, institutional and industrial buildings. As the industry has matured, standards have risen steadily to assure unquestioned performance of both exterior and interior units. Exterior units are made of dense aggregates such as sand - gravel. It is heavy, water-resident, and when properly made, exceeds minimums for load and tensile strength by 100%. For interior use. Units of lightweight aggregates are advantageous and economical, is easy to handle, readily colored, strong and possess excellent insulating and sound absorbing qualities. Whatever the type of unit, Bharat Spun Pipe & Construction Co. strive constantly to maintain (and improve where possible) the quality of concrete block. We carefully possible) the quality of concrete block. We carefully control aggregate size, proportions and cleanliness, the amount of water and cement in the mix, mixing time and thoroughness, curing and storing. No step is overlooked, at any phase of production, to assure the highest possible quality in every unit produced. ADVANTAGES OF USING CONCRETE HOLLOW BLOCKS

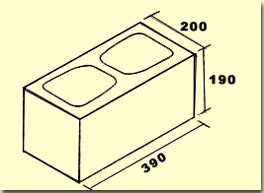

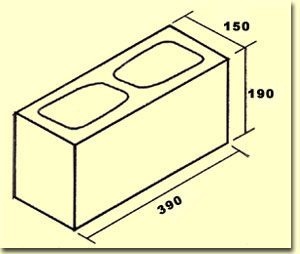

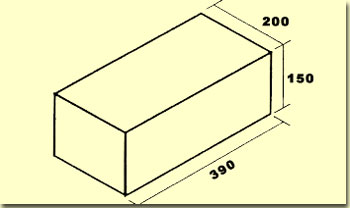

TECHNICAL DATA :- Our products comply with requirements specified in the relevant Inida Standards Viz. IS :2185 (Part I)- 1979. Specification for Concrete Masonry Units, Hollow and Solid Concrete Block and we are fully backed by M/s Columbia Machine Inc. USA who are one of the leader in this field. TYPE OF BLOCKS :- A Hollow ( Open & Close cavity) Blocks B Solid Blocks NOMINAL DIMENSIONS OF CONCRETE BLOCKS

Actual dimensions of height and length shall be 10 mm less than the nominal dimensions being thickness of mortar joint. TOLERANCES:-

COMPRESSIVE STRENGTH:-

WATER ABSORPTION :- As per relevant IS standards TESTING FACILITIES:- A complete testing laboratory for testing of hollow block, solid block and interlocking paving block confirming to relevant standards installed at our block plant. STANDARD UNITS

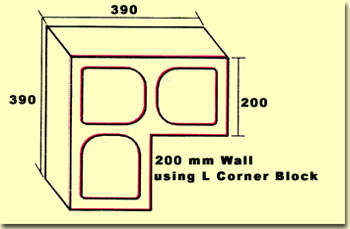

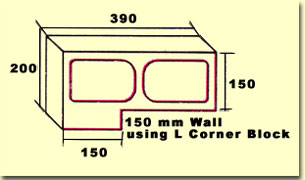

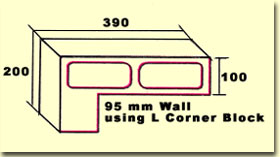

CORNER BLOCKS

PARTITION UNITS

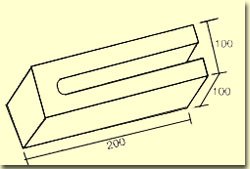

LINTEL BLOCKS :-

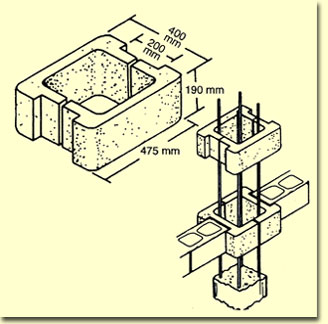

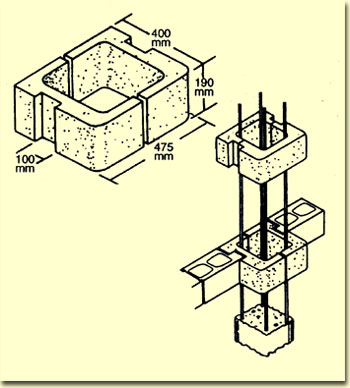

PILASTER UNITS

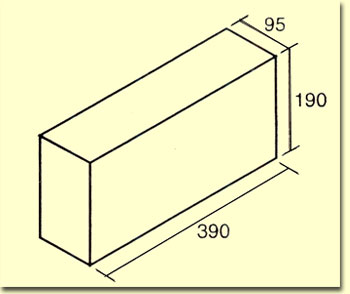

CONCRETE BRICK :-

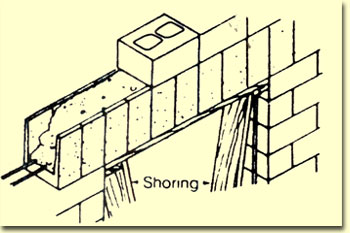

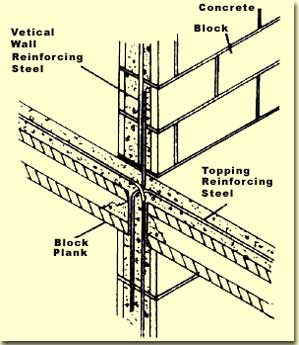

SEISMIC ZONE CONSTRUCTION :-

HIGH RISE MASONRY STRUCTURE :-

CONCRETE INTERLOCKING PAVING BLOCK Advantage / Benefits of interlocking paving Blocks The solid interlocking type has the unique ability to transfer loads and stresses laterally by means of an arching of bridging action between units. Spreading the load over a large area reduces the stress there by allowing heavier loads and traffic over sub - bases which normally would require concrete that is heavily reinforced with steel. The solid interlocking units are available in a variety of colors and patterns, thereby permitting interesting designs in paved areas which are usually plain and dull when paved with asphalt or concrete. In addition to breaking the monotony of the flat paved area, colored concrete paving stone can be used to permanently mark such things as parking bays, traffic lanes and crosswalks. Concrete paving stone offer an ecological solution to man's increasing concern for his environment - the problem of putting the moisture from rainfall back into earth rather than let it run off as waster. This is especially true when the open type stone is used . As shown in the table (right), solid interlocking paving stone are available in different thicknesses ranging from 60 mm to 100 mm. The thicker units are used for heavier service, streets, industrial floors, etc. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

To implement the stated quality policy and to achieve the objectives, the Company has a simple but well functional organization to administer all its activities, showing clear responsibilities and reporting channel.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Quality Management System ensures that all processes are proven reliable statistically and inspection points are strategically planned to detect any non-conformity at its origin. This is backed up by ongoing effort at continuous improvement, through a system of Internal Quality Audits and Management Reviews.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||